- Benefits of Laser Cleaning for Nickel Surfaces

- Comparison of Laser Cleaning vs. Traditional Cleaning Methods for Nickel Surfaces

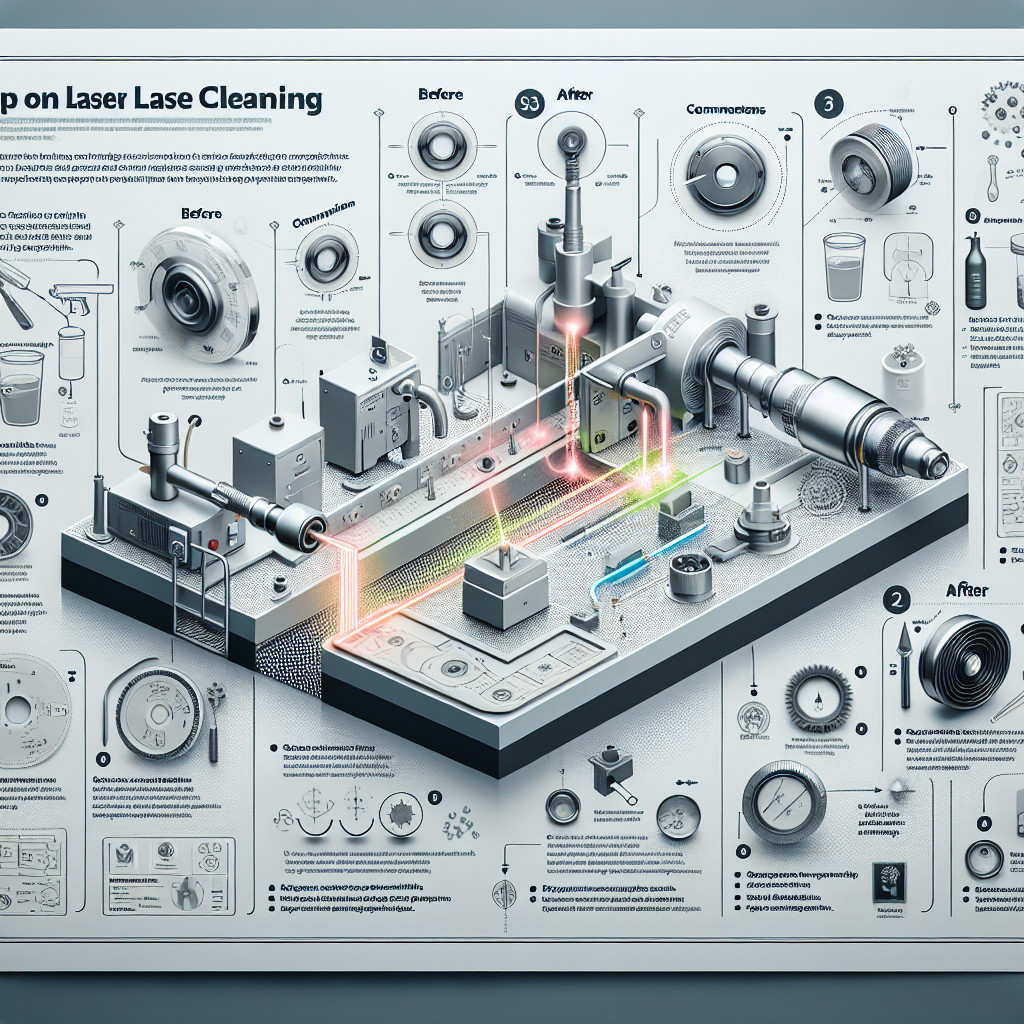

- Laser Cleaning Techniques for Removing Contaminants from Nickel Surfaces

- Case Studies of Laser Cleaning Success on Nickel Surfaces

- Safety Considerations for Laser Cleaning on Nickel Surfaces

Benefits of Laser Cleaning for Nickel Surfaces

Laser cleaning offers a more efficient, cost-effective, and environmentally friendly solution for cleaning nickel surfaces.

Advantages of Laser Cleaning for Nickel Surfaces:

- Non-contact cleaning: Laser cleaning is a non-contact process, which means that there is no physical contact between the cleaning equipment and the surface being cleaned. This eliminates the risk of damage to the nickel surface and ensures a gentle yet effective cleaning process.

- Precision cleaning: Laser cleaning allows for precise control over the cleaning process, enabling operators to remove contaminants with high accuracy and consistency. This is particularly important for delicate nickel surfaces that require careful handling.

- No chemicals or abrasives: Laser cleaning does not require the use of chemicals or abrasives, making it a safer and more environmentally friendly cleaning method. This eliminates the need for hazardous chemicals and reduces waste generation, making it a sustainable cleaning solution.

- Efficient cleaning: Laser cleaning is a fast and efficient process that can remove contaminants from nickel surfaces quickly and effectively. This can help to reduce downtime and increase productivity in industrial settings where cleanliness is crucial.

- Cost-effective: While the initial investment in laser cleaning equipment may be higher than traditional cleaning methods, the long-term cost savings can be significant. Laser cleaning requires less labor, fewer consumables, and lower maintenance costs, making it a cost-effective cleaning solution in the long run.

- Versatile cleaning capabilities: Laser cleaning can be used to remove a wide range of contaminants from nickel surfaces, including rust, paint, grease, and oxides. This versatility makes it a valuable tool for cleaning various types of nickel components in different industries.

Applications of Laser Cleaning for Nickel Surfaces:

Laser cleaning is widely used in industries such as aerospace, automotive, electronics, and manufacturing for cleaning nickel surfaces. Some common applications of laser cleaning for nickel surfaces include:

- Preparation for welding: Laser cleaning can be used to remove contaminants from nickel surfaces before welding, ensuring a clean and strong bond between the materials.

- Surface preparation: Laser cleaning can be used to prepare nickel surfaces for coating, painting, or other surface treatments, ensuring optimal adhesion and performance of the applied materials.

- Maintenance cleaning: Laser cleaning can be used for routine maintenance cleaning of nickel components to prevent corrosion, improve performance, and extend the lifespan of the materials.

- Rust removal: Laser cleaning can effectively remove rust and corrosion from nickel surfaces, restoring their appearance and functionality.

- Historical restoration: Laser cleaning can be used for the restoration of historical nickel artifacts, monuments, and structures, preserving their original beauty and integrity.

Overall, laser cleaning offers numerous benefits for cleaning nickel surfaces, including efficiency, precision, cost-effectiveness, and environmental sustainability. It is a versatile and reliable cleaning method that can help industries maintain the cleanliness and integrity of their nickel components.

Comparison of Laser Cleaning vs. Traditional Cleaning Methods for Nickel Surfaces

Laser Cleaning

Laser cleaning is a modern and efficient method of removing contaminants from nickel surfaces. It involves using a high-energy laser beam to vaporize the impurities without damaging the underlying material. Laser cleaning is non-contact, which means there is no physical contact between the cleaning tool and the surface, reducing the risk of scratching or damaging the nickel surface.

One of the key advantages of laser cleaning is its precision. The laser beam can be focused on specific areas of the nickel surface, allowing for targeted cleaning. This is particularly useful for intricate or delicate surfaces where traditional cleaning methods may be too abrasive.

Another benefit of laser cleaning is its environmental friendliness. Unlike traditional cleaning methods that use harsh chemicals or abrasive materials, laser cleaning is a dry process that does not produce any waste or emissions. This makes it a more sustainable and eco-friendly option for cleaning nickel surfaces.

Traditional Cleaning Methods

Traditional cleaning methods for nickel surfaces include abrasive cleaning, chemical cleaning, and mechanical cleaning. Abrasive cleaning involves using abrasive materials such as sandpaper or wire brushes to scrub away contaminants. Chemical cleaning uses harsh chemicals to dissolve or loosen the impurities, while mechanical cleaning involves using tools such as brushes or sponges to physically remove the contaminants.

While traditional cleaning methods can be effective in removing contaminants from nickel surfaces, they have some drawbacks. Abrasive cleaning can be too harsh and may damage the surface, while chemical cleaning can be harmful to the environment and pose health risks to workers. Mechanical cleaning may not be as precise as laser cleaning and can be time-consuming.

Comparison

When comparing laser cleaning to traditional cleaning methods for nickel surfaces, several factors should be considered. These include efficiency, precision, environmental impact, and cost.

- Efficiency: Laser cleaning is generally more efficient than traditional cleaning methods as it can remove contaminants quickly and effectively without damaging the surface.

- Precision: Laser cleaning offers greater precision and control over the cleaning process, allowing for targeted cleaning of specific areas.

- Environmental Impact: Laser cleaning is a more environmentally friendly option as it does not produce any waste or emissions, unlike traditional cleaning methods that may use harsh chemicals or abrasive materials.

- Cost: While laser cleaning may have a higher upfront cost, it can be more cost-effective in the long run due to its efficiency and reduced need for maintenance.

In conclusion, laser cleaning is a superior method for cleaning nickel surfaces compared to traditional cleaning methods. It offers greater efficiency, precision, and environmental friendliness, making it a more sustainable and effective option for maintaining the quality of nickel surfaces.

Laser Cleaning Techniques for Removing Contaminants from Nickel Surfaces

How Laser Cleaning Works

Laser cleaning is a non-contact, non-abrasive cleaning method that uses a high-energy laser beam to remove contaminants from surfaces. When the laser beam hits the surface, it vaporizes the contaminants, leaving behind a clean and residue-free surface. The process is highly precise and can be controlled to remove only the contaminants without damaging the underlying material.

Benefits of Laser Cleaning

- Fast and efficient: Laser cleaning can remove contaminants from nickel surfaces in a fraction of the time compared to traditional cleaning methods.

- Eco-friendly: Laser cleaning does not require the use of chemicals or abrasive materials, making it a more environmentally friendly option.

- Precision: Laser cleaning can be controlled to remove contaminants with high precision, minimizing the risk of damage to the underlying material.

- Cost-effective: While the initial investment in laser cleaning equipment may be higher, the long-term cost savings from reduced labor and material costs make it a cost-effective cleaning solution.

Applications of Laser Cleaning on Nickel Surfaces

Laser cleaning techniques can be used in a wide range of industries for cleaning nickel surfaces, including:

- Automotive: Removing rust and paint from nickel-plated automotive parts.

- Aerospace: Cleaning contaminants from nickel surfaces on aircraft components.

- Electronics: Removing solder and flux residues from nickel-plated electronic components.

- Medical: Cleaning surgical instruments and medical devices with nickel surfaces.

Challenges and Considerations

While laser cleaning offers many benefits, there are some challenges and considerations to keep in mind when using this technique on nickel surfaces:

- Surface preparation: Proper surface preparation is essential to ensure the effectiveness of laser cleaning. Surfaces should be free of oils, greases, and other contaminants that may interfere with the cleaning process.

- Material compatibility: Not all materials are suitable for laser cleaning. It is important to test the compatibility of the nickel surface with the laser cleaning process to avoid damage or discoloration.

- Safety precautions: Laser cleaning involves the use of high-energy lasers, so proper safety precautions should be taken to protect operators from potential hazards.

Conclusion

Laser cleaning techniques offer a fast, efficient, and eco-friendly solution for removing contaminants from nickel surfaces. With proper surface preparation, material compatibility testing, and safety precautions, laser cleaning can be a highly effective cleaning method for a wide range of industries. By utilizing laser cleaning techniques, companies can improve the cleanliness and quality of their nickel surfaces while reducing their environmental impact.

Case Studies of Laser Cleaning Success on Nickel Surfaces

Case Study 1: Aerospace Industry

In the aerospace industry, nickel surfaces are often exposed to harsh environments that can lead to the accumulation of contaminants and oxides. One aerospace company decided to test the effectiveness of laser cleaning on their nickel components. They found that laser cleaning not only removed all contaminants and oxides from the surface but also improved the overall surface quality. This resulted in improved performance and longevity of the components.

Case Study 2: Automotive Industry

In the automotive industry, nickel surfaces are commonly used in various components, such as engine parts and exhaust systems. A leading automotive manufacturer conducted a study to evaluate the benefits of laser cleaning on nickel surfaces. They found that laser cleaning not only removed all contaminants and oxides but also improved the adhesion of coatings applied to the surface. This resulted in enhanced durability and corrosion resistance of the components.

Case Study 3: Electronics Industry

In the electronics industry, nickel surfaces are often used in connectors and other components that require high precision and cleanliness. A major electronics manufacturer tested the effectiveness of laser cleaning on their nickel components and found that it significantly improved the electrical conductivity of the surfaces. This led to improved performance and reliability of the components.

Case Study 4: Medical Industry

In the medical industry, nickel surfaces are used in various medical devices and equipment. A medical device manufacturer conducted a study to assess the impact of laser cleaning on their nickel components. They found that laser cleaning not only removed all contaminants and oxides but also improved the biocompatibility of the surfaces. This resulted in safer and more reliable medical devices.

Conclusion

These case studies demonstrate the effectiveness of laser cleaning on nickel surfaces in various industries. Laser cleaning not only removes contaminants and oxides but also improves surface quality, adhesion of coatings, electrical conductivity, and biocompatibility. This results in improved performance, durability, and reliability of components. As a result, laser cleaning has become a preferred method for cleaning nickel surfaces in many industries.

Safety Considerations for Laser Cleaning on Nickel Surfaces

Laser cleaning is a highly effective method for removing contaminants and oxides from nickel surfaces. However, it is important to consider safety precautions when using this technology to prevent accidents and ensure the well-being of operators. Here are some key safety considerations to keep in mind when performing laser cleaning on nickel surfaces:

1. Protective Eyewear: Laser cleaning generates intense light that can cause eye damage if proper precautions are not taken. Operators should always wear appropriate laser safety glasses that are designed to block the specific wavelength of the laser being used.

2. Proper Ventilation: Laser cleaning can produce fumes and particles that may be harmful if inhaled. It is important to ensure that the work area is well-ventilated to prevent the buildup of hazardous substances. Additionally, operators should wear respiratory protection if necessary.

3. Fire Safety: Laser cleaning can generate heat that may ignite flammable materials in the vicinity. It is important to remove any combustible materials from the work area and have fire extinguishing equipment readily available in case of emergencies.

4. Personal Protective Equipment: In addition to protective eyewear and respiratory protection, operators should wear appropriate clothing and gloves to protect their skin from potential burns or injuries.

5. Training and Certification: Operators should be properly trained in the use of laser cleaning equipment and have the necessary certifications to operate the technology safely. It is important to follow manufacturer guidelines and best practices to minimize risks.

6. Controlled Environment: Laser cleaning should be performed in a controlled environment to prevent accidents and ensure the safety of operators. This includes securing the work area, restricting access to unauthorized personnel, and implementing safety protocols.

7. Emergency Procedures: In the event of an accident or injury during laser cleaning, operators should be familiar with emergency procedures and know how to respond quickly and effectively. This may include first aid training and access to emergency medical services.

8. Regular Maintenance: Laser cleaning equipment should be regularly inspected and maintained to ensure optimal performance and safety. Any damaged or malfunctioning components should be repaired or replaced promptly to prevent accidents.

9. Risk Assessment: Before performing laser cleaning on nickel surfaces, operators should conduct a thorough risk assessment to identify potential hazards and implement appropriate safety measures. This may include conducting a hazard analysis and developing a safety plan.

10. Compliance with Regulations: It is important to comply with all relevant regulations and standards governing the use of laser cleaning technology. This includes following OSHA guidelines, ANSI standards, and any other applicable regulations to ensure a safe working environment.

In conclusion, laser cleaning on nickel surfaces can be a highly effective method for removing contaminants and oxides, but it is essential to prioritize safety considerations to prevent accidents and protect the well-being of operators. By following proper safety protocols, wearing protective equipment, and maintaining a controlled environment, operators can minimize risks and ensure a safe and successful laser cleaning process.